CYCO Dry Fog Humidifier Nozzle System

Dry Fog Humidifier Nozzle System Video

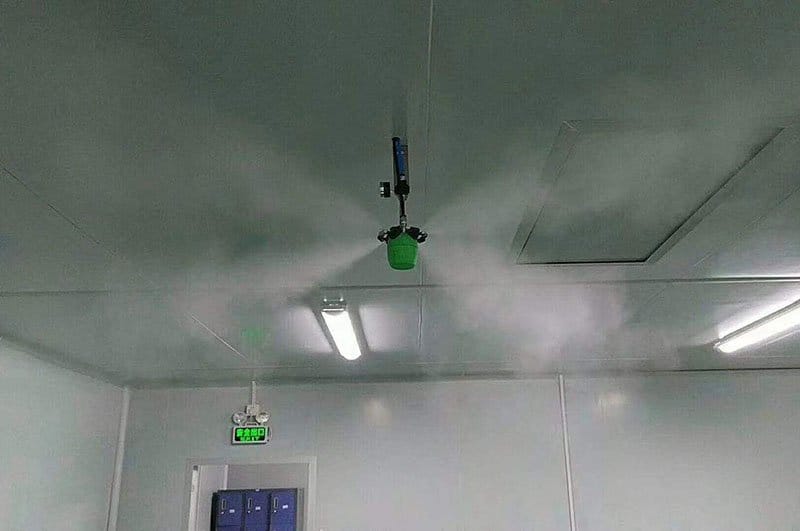

CYCO Dry Fog Humidifier System used for humidification and cooling purpose, it sprays a none wetting fog ideal for clean rooms, electronics industry and other sensitive working environment where wetting is an issue. With extreme portability, simple maintenance, adjustable spray angles, and precise humidity control, the high quality CYCO Humidifier Nozzle is an affordable, effective, and proven solution for your humidification and cooling needs.

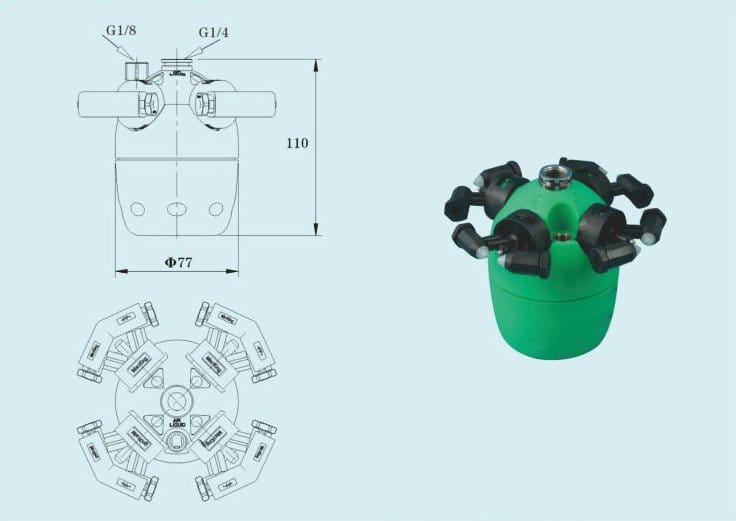

Dry fog humidification system through gas and water two fluid mixing, and then through three times of gasification shear, the supersonic air from the nozzle is again particulate, and from the other nozzle is also the same particulate air in the center of the impact, repeatedly cut each other at the same time, 33,000-40,000 Hertz ultrasonic will be more particulate droplets. The principle of equalization atomization system realizes multi-stage atomization and achieves good spray effect. The diameter of spray particles is 5-7.5um.

Introduction Of Spray Humidification System

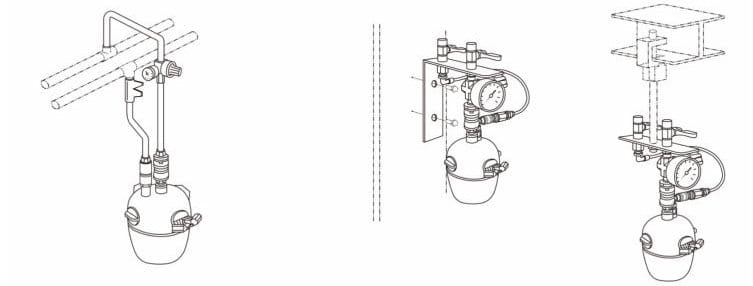

The spray humidification system is composed of a dry mist humidifier + control components + installation components + air/water pipelines + humidity detection equipment + water quality filtration equipment.

The purpose of spray humidification is to artificially create mist through the spray humidification system. The particle size of this water mist is very small and can float in the air, and this fine mist can float in the air for a long time to reach the surrounding air. The effect of humidification, and will not wet materials and walls. Spray humidification not only has the effect of humidifying the surrounding air, but also has a certain cooling effect, anti-static effect (high humidity, the generation of static electricity is reduced), dust reduction, dust suppression and other effects.

Features of Dry Fog Humidifier Nozzle

- High performance humidifier, most compact in the world, maximum humidifying capacity up to 9.6L/h (air pressure is 0.3MPa).

- Quick disassembly, easy maintenance

- Remarkable humidification effect, the national patented dry fog humidifier nozzle provides high-quality mist spray, with jet length over 4mm.

- Use ultra-small water storage tanks, which can’t easily multiply bacteria.

- Adopt high-tech nozzles, not easy to be blocked.

- Automatic control by timer and controller.

- No need to clean the humidifier if a pure water processor is used.

Advantages of spray humidification system

- 1. The average particle size is 7.5μm micron;

- 2.The spray volume (one nozzle) is 2.4L/H and the air pressure is 0.3MPa;

- 3. At most 4 nozzles can be installed, and the installation and disassembly are convenient;

- 4. The high-quality AE series nozzles bring you ultra-dry mist particles with a silk-like feel;

- 5. It is more suitable for humidification in a small space and will not wet the wall;

- 6. Automatic operation, automatic induction of air humidity, automatic humidification at a lower value, and automatically stop working when the target humidity is reached;

- 7. The spray direction can be adjusted arbitrarily;

- 8. Energy saving and consumption reduction, more than 50% energy saving compared with other humidification systems, and higher humidification efficiency;

- 9. It can be equipped with mobile accessories, no pipeline installation, more convenient and quick, spray humidification anytime and anywhere.

Main Industries of Application

CYCO Dry Fog Humidifier Nozzle System Main Industries of Application

Printing / Food / Electronics / Automotive / Painting / Agriculture and livestock / Chemical / Textile / Paper and Pulp / Plastic/ Ceramic / Air conditioning It is ideal for humidification in narrow space without wetting the wall.

Application of spray humidification system

- 1. Humidification: used in textile mills, cotton wool warehouses, parks, greenhouses, laboratories, and flour mills to increase air humidity;

- 2. Dust removal: the removal of air dust particles is mainly used in farms and mines to control pollution;

- 3. Cooling down: cooling of outdoor restaurants, entertainment venues, gymnasiums, sports fields, airports, bus stations, large gatherings, hotels, and livestock farms;

- 4. Agriculture: used in family farms, mushroom cultivation field, circus arena, bird house, doghouse and feeding field to make the environment suitable for the growth of various poultry;

- 5. Industry: metalworking workshop, machinery workshop, textile workshop, garment workshop, printing and dyeing, shoemaking, plastic injection, die-casting, heat treatment, casting, glass products, spraying, electroplating, electronics, chemical metallurgy, leather, toy manufacturing, home appliance manufacturing, etc., used for cooling and dust removal, and also used to eliminate electrostatic interference;

- 6. Special use places: Humidification and cooling of garden, zoo, shopping center, exhibition, cinema, flower and tree breeding, animal husbandry, mushroom house, etc., and can also be used as plant irrigation;

- 7. Special use method: adding liquid disinfectant to the water can disinfect botanical gardens, greenhouses, livestock farms, zoos, golf courses, etc.

Installation kit

Performance

Airpressure

(MPa)

Capacity

(L/H)

Air consumptipn

(N.L/min)

0.3

2.4

29

0.35

2.7

32.5

AE Series

Capacity

(L/H)

Air consumptipn

(N.L/min)

Number of Nozzles

2.4

29

1

4.8

58

2

7.2

87

3

9.6

116

4

Dry Fog Humidifier Equipment Test Report

Micro Mist Humidification System

Product Features:

- 1. Low energy consumption: Each unit consumes only 2.2-4KW per hour, which is about 1/50 of the energy consumption of traditional air-conditioning dust reduction.

- 2. Low cost: Low purchase cost, only about 1/25 of traditional air humidification dust reduction.

- 3. Large spraying capacity: Each unit can meet the dust reduction requirements for an area of around 6000 square meters.

- 4. High quality: The core components of the main unit are imported from Germany, with a lifespan exceeding eight years. The PLC intelligent human-machine interface control ensures true maintenance-free operation.

Product Functions:

- 1. Micro-mist dust reduction: Utilizing water from the tap, wells, or fire reservoirs through the dust reduction system to create airborne water mist, which adsorbs dust particles and impurities in the air. Under conditions where the on-site wind speed is below level two, it can reduce particle concentration in the air by 85%. After misting for a certain period at height, it moistens the ground, effectively suppressing dust from rising again.

- 2. Micro-mist maintenance: During the entire construction period, the water quantity of the nozzles can be adjusted according to the actual site conditions to maintain the main structure.

- 3. Micro-mist cooling: In the summer, the surface temperature of the construction site approaches 50°C, making work extremely difficult. However, by using our spray dust reduction system with timed spraying, it effectively achieves "artificial rainfall" on the construction site, reducing the site temperature by 2-4 degrees Celsius, improving the working environment, and reducing the probability of heatstroke among workers.

Working Principle:

High-pressure plunger pumps raise the water pressure to 4-7Mpa, and then pressurized water is atomized through nozzles via high-pressure delivery pipelines. This generates micro-mist particles ranging from 3-15 micrometers, allowing them to quickly combine with airborne dust and settle, thereby achieving the goal of dust reduction.

Product Applicable Areas:

- 1. Gravel plants, building material factories: Implementing gravity dust reduction and water mist pressure dust reduction in areas where dust is difficult to contain, such as automatic conveying systems and material stacking areas.

- 2. Coal plants, power plants: Addressing challenges of dust dispersion in areas with difficult enclosure, such as automatic coal conveying systems and various dust material transport system transfer points.

- 3. Cement plants: Cement dust pollution is a well-known issue, and the spray dust reduction system is a good choice for improving the environment in cement plants.

- 4. Mixing stations: Due to the special nature of material mixing in mixing stations, fine dust pollution is severe, making the spray dust reduction system with its uniform spraying, fast dust reduction, and high efficiency particularly suitable.

- 5. Wood processing industry: Dust pollution is a significant contributor to smog. Therefore, effective and scientific dust suppression methods are sought after in places facing dust pollution, such as wood processing workshops. The spray dust reduction system is widely used in places prone to dust, such as wood processing workshops, stone processing factories, and cement plants, due to the requirements of environmental protection and the need for sustainable development.