Working principle:

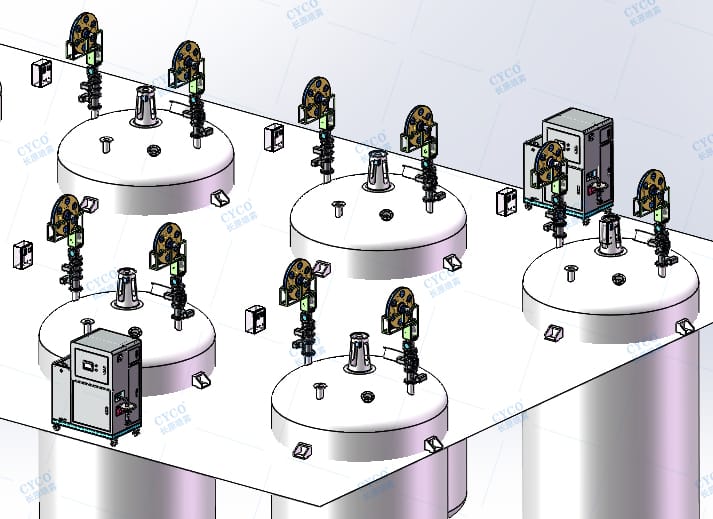

The reel-type reactor cleaning system consists of a reel telescopic device, a high-pressure pump, a three-dimensional rotating cleaning nozzle, and an intelligent operation PLC platform. The lifting height is more than 1 meter, which is suitable for cleaning medium and large reactor walls.

The reel-type lifting mechanism uses a motor to drive the reel to control the retraction and extension of the telescopic rod, and is equipped with a three-dimensional rotating reactor cleaning nozzle to achieve comprehensive cleaning of the inner wall of the reactor. It can achieve fixed-point cleaning and stay at different depths inside the reactor. The length can be customized according to the depth and size of the reactor. It is convenient to store and does not occupy space. The reel is automatically retracted and easy to operate.

Product features:

1. PLC intelligent operation platform, one machine can carry multiple reel cleaning devices.

2. Reel-type vertical lifting, precise positioning, and fixed-point and timed cleaning.

3. The cleaning pipeline can be automatically retracted to avoid pipeline entanglement and wear, and increase service life.

4. Save time, labor and water, and clean efficiently and thoroughly.

5. 5-350 kg cleaning pressure is optional, and stubborn stains can be easily removed.

Application areas:

Widely used for cleaning of reactors in pharmaceutical, food, beverage, coating, building materials, chemical, pigment, resin, scientific research, dairy, daily chemicals, cosmetics, bioengineering, agricultural engineering, processing tools, petroleum, new energy, etc.

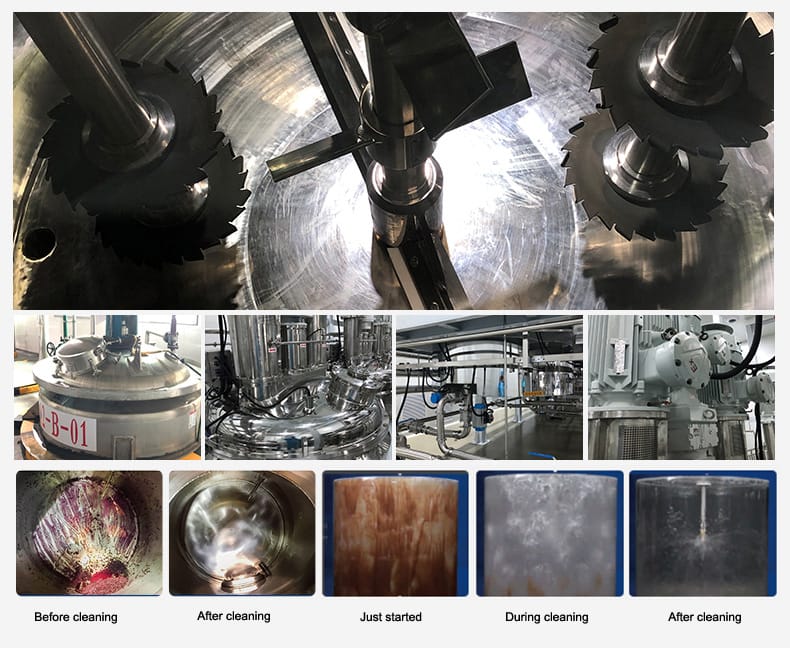

Cleaning Effect