Working principle:

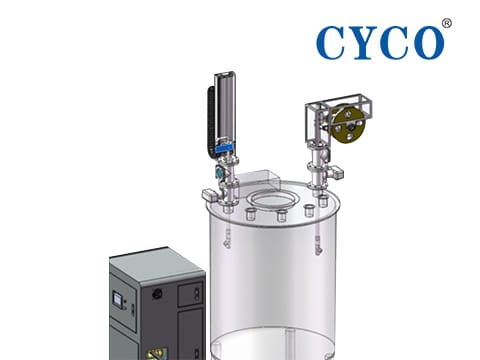

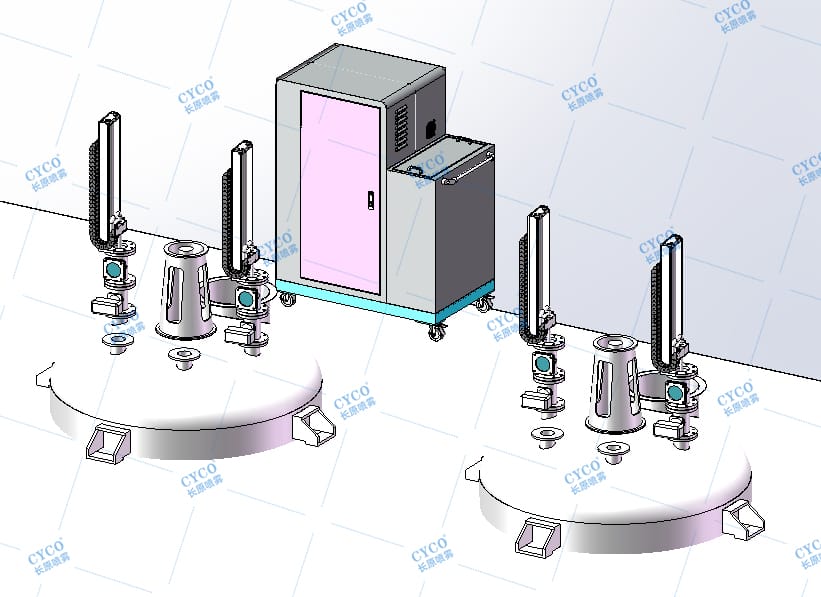

The telescopic height of the cylinder telescopic cleaning system for reactors is less than 1 meter, which is suitable for cleaning small and medium-sized reactors. The cleaning device is driven by a cylinder or a hydraulic cylinder to perform telescopic movement, which can accurately control the position and angle of the cleaning head.

It consists of a cylinder, a bracket, a flange, a nozzle connecting rod, a reactor cleaning nozzle, a high-pressure pump, a pipeline, a control system, etc. The control system includes a pneumatic control or a hydraulic control unit to achieve precise adjustment of the telescopic length, speed and position.

Product features:

1. High flexibility: The telescopic action of the cylinder can accurately adjust the position of the cleaning head, which is suitable for reactors with complex internal structures.

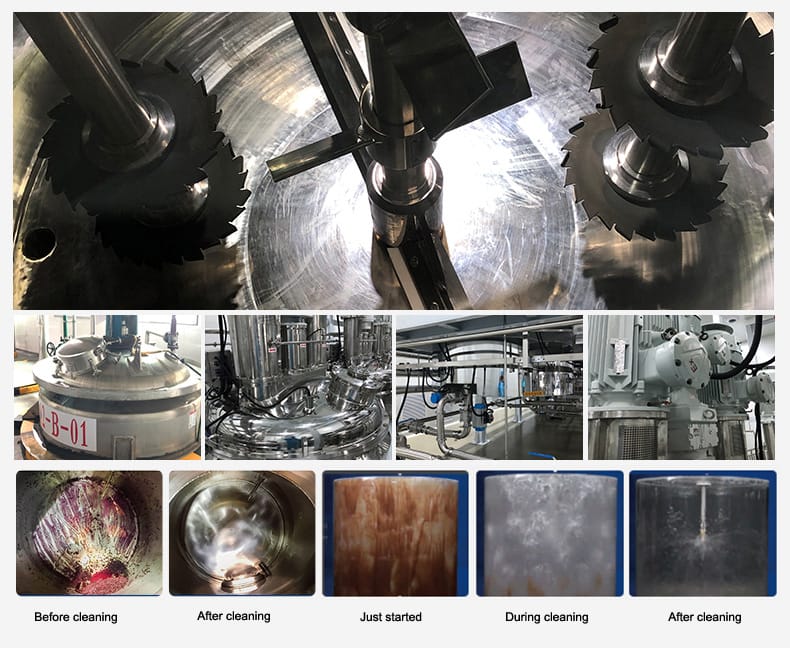

2. Efficient cleaning: Equipped with a reactor washing nozzle, it can effectively remove adhesions, scaling and residues on the reactor wall.

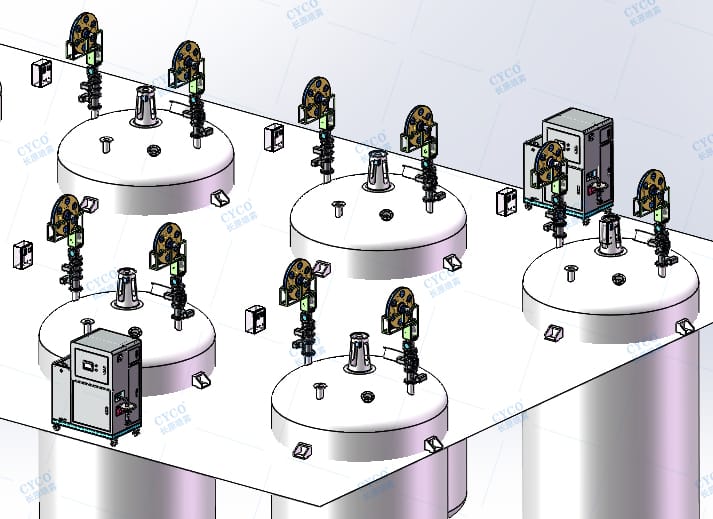

4. One machine can carry multiple cylinder cleaning devices: PLC control system can realize automatic telescopic and fixed-point cleaning, reducing manual intervention.

5. Increase production and save energy: Precise cleaning reduces the waste of cleaning agents and water.

Application fields of cylinder telescopic kettle cleaning equipment:

Widely used for cleaning of many reactors in pharmaceutical, food, beverage, coating, building materials, chemical, pigment, resin, scientific research, dairy, daily chemical, cosmetics, bioengineering, agricultural engineering, processing tools, petroleum, new energy, etc.

Cleaning Effect