Pharmaceutical kettles are used for mixing, heating, cooling, reaction and storage in drug production. They are divided into reactors, batching kettles, liquid storage kettles, evaporators, crystallizers, fermenters, stainless steel heating kettles, autoclaves, multifunctional kettles and other models.

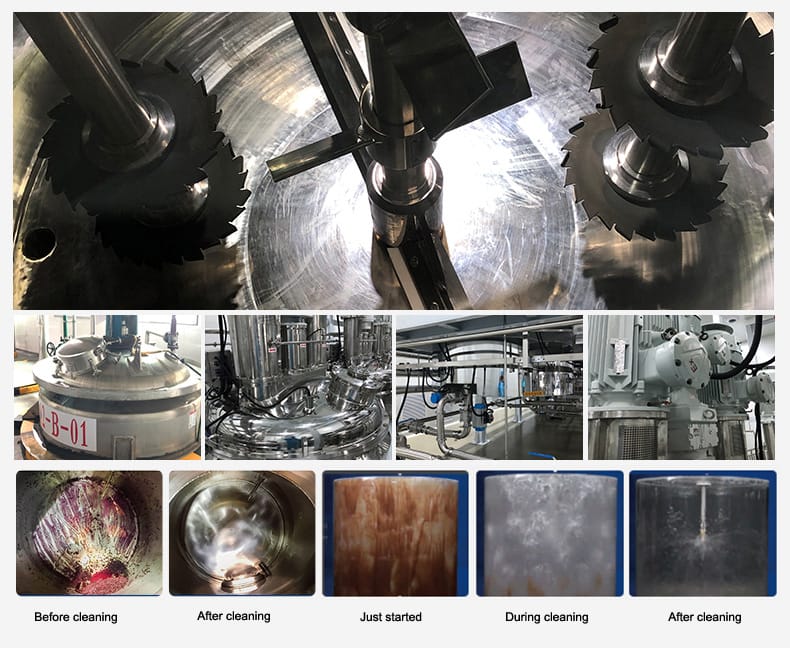

Pharmaceutical kettle cleaning problems: There may be complex geometric structures inside (such as stirring paddles, dead corners, welds, etc.), which are easy to form cleaning blind spots. High-viscosity materials or crystalline substances are easy to adhere to the kettle wall and stirring paddles, making them difficult to clean. If the cleaning is not thorough, it may cause microbial growth and affect the quality and safety of the drug.

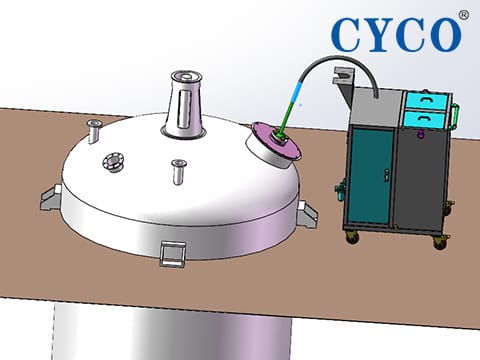

The automatic lifting and cleaning system equipment for pharmaceutical kettles produced by CYCO Spray uses a combination of three-dimensional rotating cleaning nozzles, fixed cleaning nozzles, high-pressure cleaning nozzles, PTFE cleaning balls and rotating spray balls. The lifting methods include reel type, electric type, cylinder type, etc., PLC semi-automatic or fully automatic operation mode, one-button start cleaning, and full coverage fixed-point cleaning. Crystals and other residues in the kettle can be completely removed, and there are no dead corners on the stirring paddle, kettle bottom and other difficult-to-clean parts. Cleaning time is shortened, cleaning fluid consumption is reduced by 30%, and operating costs are greatly reduced.

Cleaning Effect