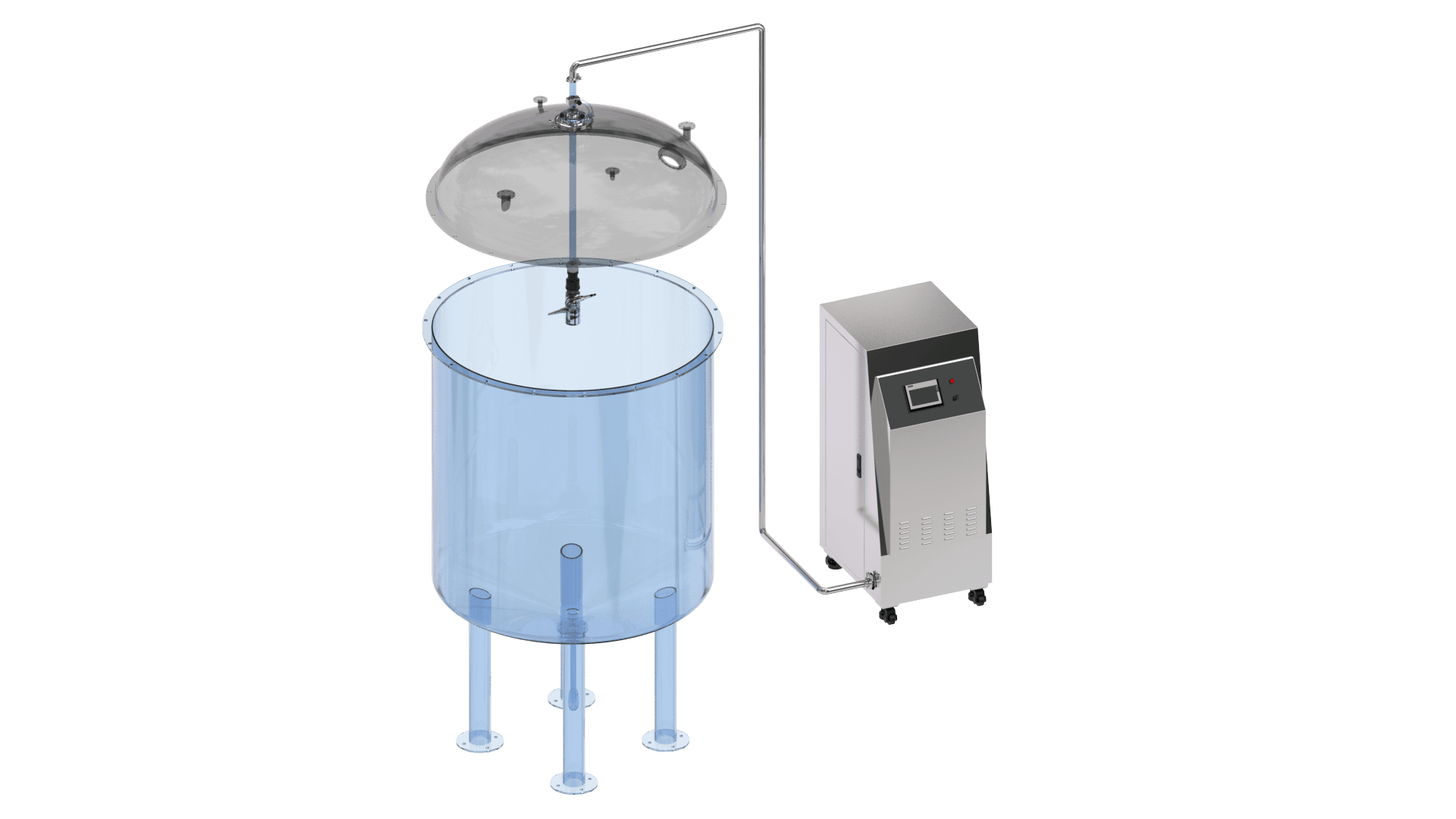

The reactor/fermentation tank automatic cleaning system is mainly used for full coverage cleaning in medium-sized cubic tanks, including fermentation tanks, mixing tanks, storage tanks, reactors, chemical tanks and other three-dimensional tank systems;

The working mode is semi-automatic control, and one-button full-automatic control can also be provided. Operators are required to monitor and control the entire cleaning process and assist. It is no longer necessary to manually enter the tank for cleaning, which adds a guarantee for the safety of workers and also reduces the workload of workers; and improves work efficiency, can greatly shorten the cleaning time, thereby saving more cleaning agents, and truly saving time, labor and cost.

Fermentation tank/reactor automatic cleaning system system overview:

This system is used for cleaning the main reactor, stirring tank, etc. The system working mode is manual operation, and the operator is required to operate the entire cleaning process and assist;

Water supply capacity – rated flow (5-8) m3/h, rated pressure 10-20 kg;

High-pressure water pump protection – anti-idling, anti-pressure overload, anti-overheating function;

Automatic start and stop – the main pump automatically starts and stops when the cleaning water starts, and the main pump automatically starts when the cleaning water starts.

When the process needs to be paused, close the cleaning water valve, and the main pump stops working and enters the waiting state. Machine state, wait

After opening the water valve again, the main pump will restart;

Manual adapter – swing angle, tilt arm, portable integrated adapter;

Imported hose – composite hose resistant to high pressure 50Bar, quick-install interface design;

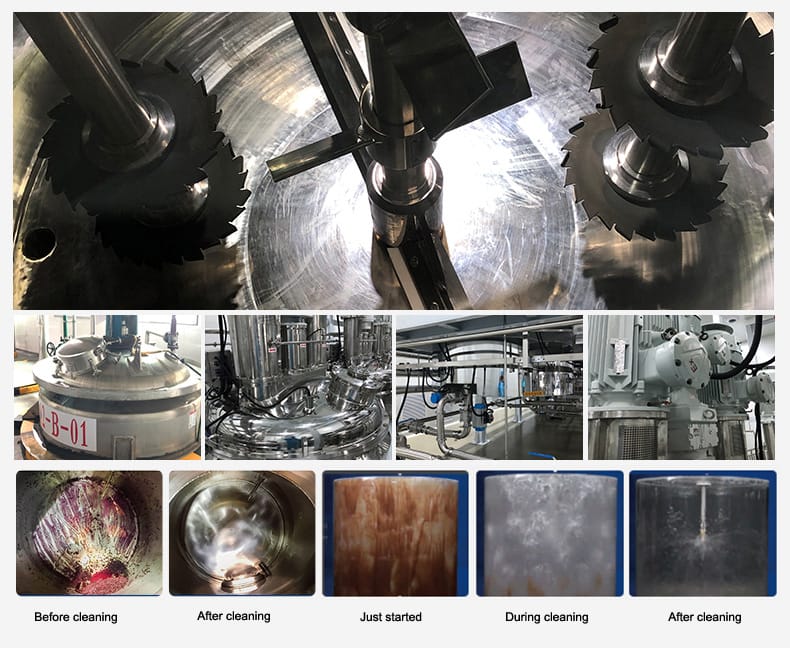

Reactor/tank automatic cleaning equipment cleaning instructions:

1. After the initial positioning, open the manhole cover, raise the mechanical arm, push the trolley, and align the center of the manhole flange on the mechanical arm (need to move the system trolley) with the center of the manhole. Manually press the lifting and lowering jog button to descend while aligning the tank manhole precisely, then lock it, and step on the foot brake on the 4 universal wheels to prevent movement. Connect water, electricity and gas, and confirm the installation and alignment seal;

2. After the operator starts the system, it enters the semi-automatic cleaning state, divided into 3 height positions, and symmetrical cleaning at 2 points along the center line of the tank, requiring manual swing arm intervention; the entire cleaning process only requires one person to control and complete; the cleaning time at each position can be set and changed manually, and the password can be entered in the specified page on the touch screen;

3. Estimated cleaning time – about 20 minutes/tank, depending on the customer’s cleanliness requirements and the size of the reactor body;

Cleaning Effect