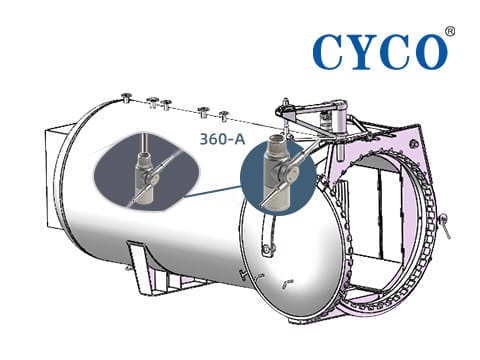

Horizontal reactors are widely used in chemical, pharmaceutical, food, material synthesis and other industries. They are mainly used for material mixing, reaction, emulsification, dispersion and other process. They often have a large volume and can withstand a certain pressure and temperature to ensure the efficiency and stability of the reaction process. Internal cleaning is relatively complicated, and CYCO reactor automatic cleaning system is often required to achieve efficient and thorough cleaning effect.

Technical parameters

Pressure range: 10-300 bar (adjustable)

Flow range: 50-150 L/min

Cleaning nozzle type: three-dimensional rotating nozzle, fixed nozzle, fan nozzle, etc.

Spray angle: 360-degree all-round spray

Spray radius: customized according to the size of the reactor, 0.5-30 meters are available

Lifting height: 0-3 meters (customized according to the height of the reactor)

Lifting speed: 0.1-1 m/s (adjustable)

Moving mode: track or wheeled movement

Moving speed: 0.1-1 m/s (adjustable)

Control mode: PLC control, touch screen operation

Remote monitoring: support remote monitoring and control

Operation mode: automatic mode, manual mode, remote control mode

Application advantages

The automatic lifting and cleaning system of the horizontal reactor can completely remove the scale on the inner wall of the reactor. It is fast, easy to operate, highly automated, and safe and environmentally friendly without people entering the tank.

Widely used in cleaning of various kettles in 200+ industries such as pharmaceuticals, food, beverages, coatings, building materials, chemicals, pigments, resins, scientific research, dairy products, daily chemicals, cosmetics, bioengineering, agricultural engineering, processing tools, petroleum, new energy, etc.

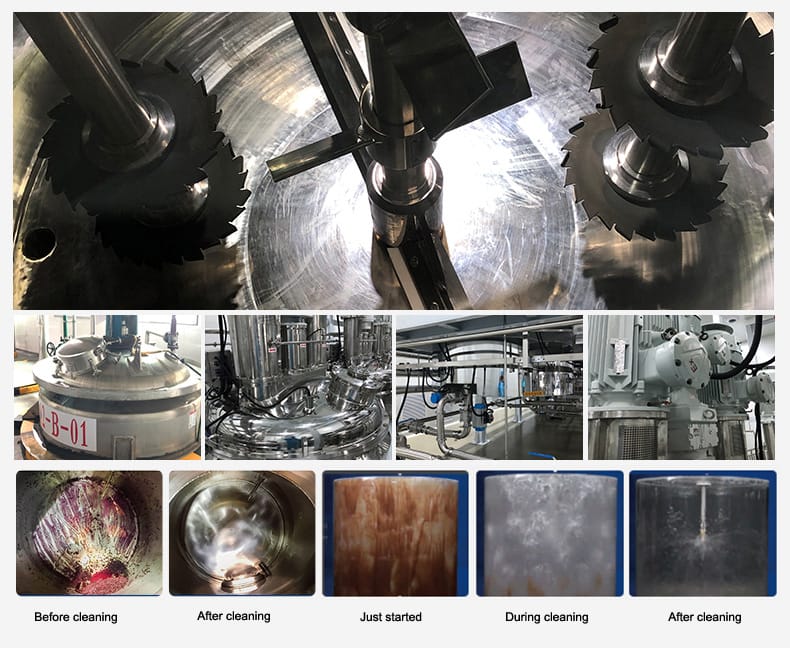

Cleaning Effect