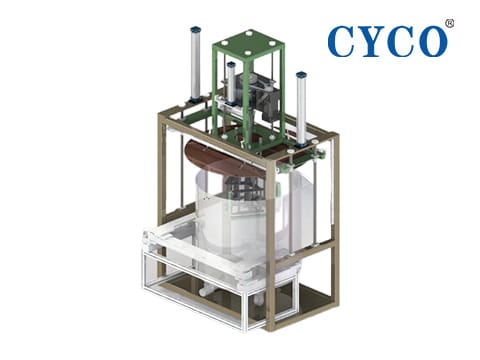

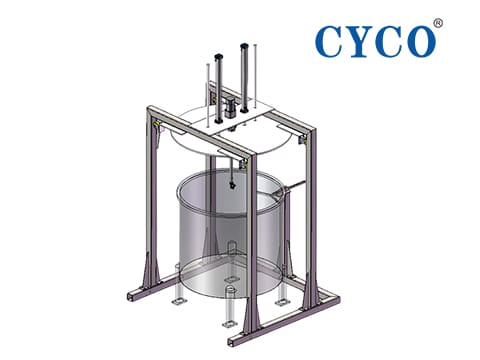

The fully automatic brush cleaning equipment for the pull cylinder adopts a telescopic cleaning brush and combines solvent spraying to achieve thorough cleaning of the cylinder wall and the bottom of the cylinder. The spindle speed is adjustable and the cleaning depth is adjustable. It is suitable for cleaning the inside of the pull cylinder, automatically adjusting the clamping positioning according to the size of the cylinder body, and is compatible with cylinder bodies of different specifications with a diameter of 500-1100mm.

Composition

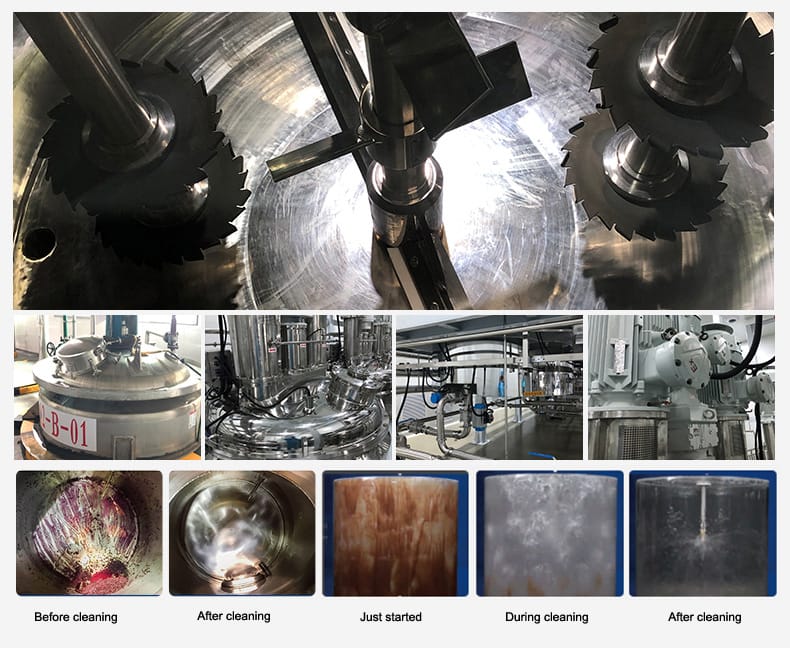

The fully automatic cleaning equipment for the pull cylinder consists of a fixed outer frame, an electric control host, an operation panel, a lifting device, a sealing upper cover, a cleaning spindle, an automatic positioning clamping device for the cylinder body, an openable and closable protective net, a three-dimensional cleaning head, a cleaning brush, etc.

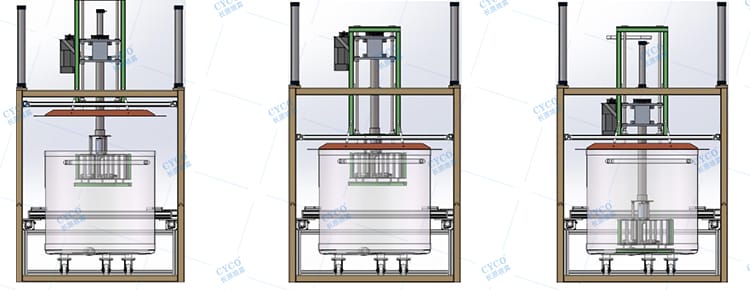

Workflow

1. Quick positioning: Use a forklift to move the pull cylinder to the cleaning station and accurately position it, close the sealing cover, and prepare for cleaning.

2. Powerful combination: Automatic lifting and rotating brushes start to accurately position and brush, combined with solvent spraying for synchronous cleaning, three-dimensional stereoscopic, blind spot-free, full coverage, and cycle cleaning.

3. Intelligent operation: Fully automatic cleaning, as long as the operator monitors and controls the entire cleaning process and assists.

Cleaning Effect