System Introduction:

CYCO CIP cleaning system (Cleaning In Place) is an ideal equipment and pipeline cleaning method, especially in food processing enterprises, such as dairy enterprises. The system can clean equipment (such as tanks, pipelines, pumps, etc.) in situ without disassembling or moving the device.

Working principle:

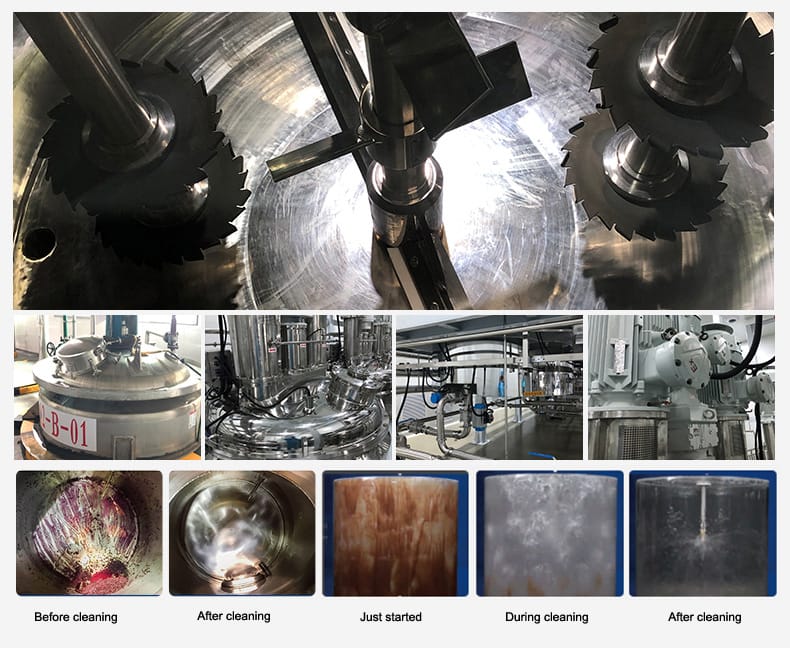

The CIP cleaning system uses a specific program and pumping system to transport water and cleaning fluid to the inside of the equipment for automatic cleaning. The cleaning process is usually carried out in closed production equipment, tank containers and pipelines, which greatly reduces the chance of secondary pollution.

Advantages and characteristics:

Stable and efficient: It adopts human-machine interface image display, which can automatically switch various process parameters such as cleaning time, PH, temperature, etc., and the operation mode can be selected manual or automatic.

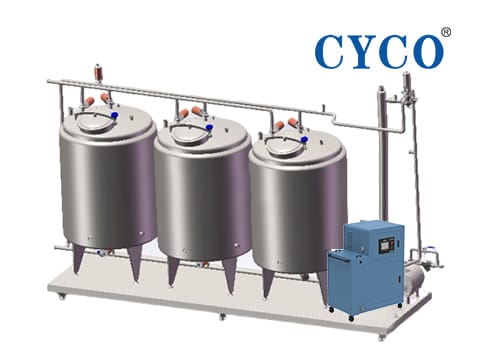

Compact structure: low economic operation cost, small footprint, easy installation and maintenance.

High degree of automation: It can automatically detect, add liquid, discharge, display and adjust the cleaning liquid, with simple operation and good cleaning effect.

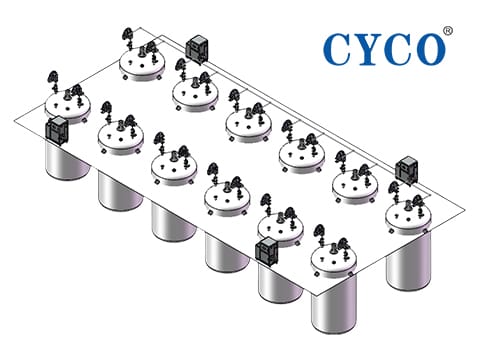

Strong adaptability: It can be divided into one to four routes according to production needs. It can not only clean the same or more than two areas in different zones at the same time, but also clean while producing.

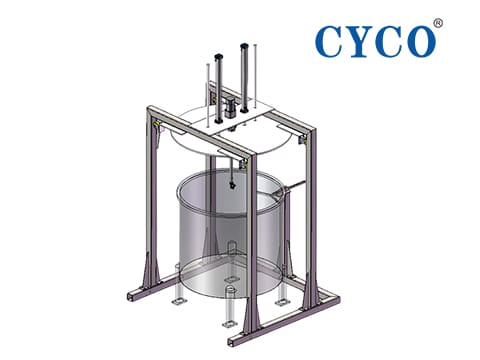

Components:

CIP system usually includes CIP blending tanks (such as CIP alkali tanks, CIP acid tanks, hot water tanks and recovery tanks), hot water tanks, centrifugal pumps, pipes, valves and pipe fittings, and CIP control cabinets.

Scope of application:

CIP cleaning system is not only used in food processing enterprises, but also widely used in beer production and other industries. Its efficient cleaning ability is essential to ensure product quality and hygiene standards.

Cleaning Effect