Working principle of biopharmaceutical tank cleaning system

CYCO fermentation tank cleaning system is an advanced cleaning technology designed to solve the problem of cleaning residues inside the fermentation tank. The system combines high-pressure water jet technology and three-dimensional rotating nozzles to achieve all-round and dead-angle cleaning of the inner wall of the fermentation tank.

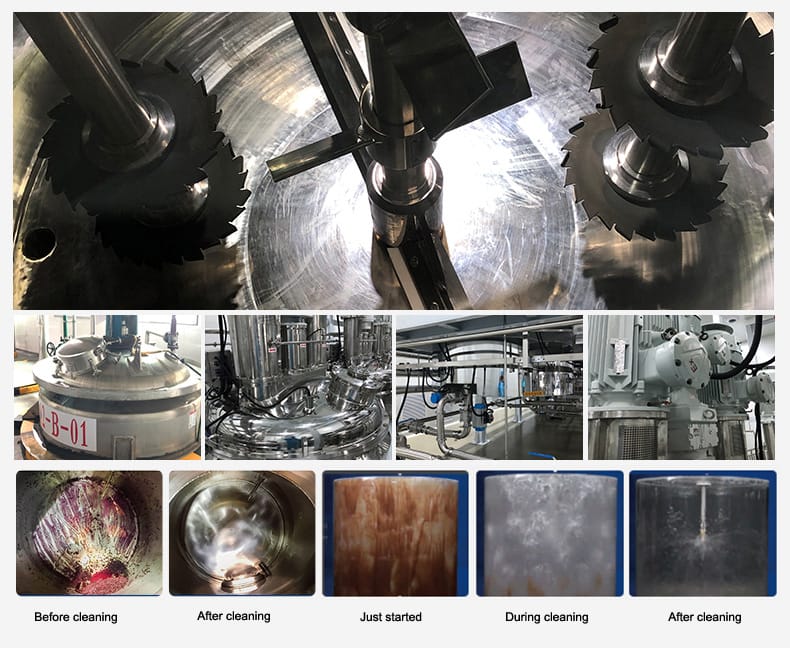

The system uses a high-pressure water pump to pressurize water to form a high-speed jet. At the same time, a special three-dimensional tank washer telescopic mechanism is installed on the fermentation tank inlet, and the telescopic rod extends into the tank. The telescopic rod is telescoped in the tank and moves around the inner wall. When the three-dimensional tank washer rotates horizontally, the rotational torque formed by the water jet drives the nozzle to rotate in the vertical plane. Due to the compound movement of the three-dimensional rotating nozzle and the telescopic rod, the high-pressure water jet can cover any position in the fermentation tank, thereby completing the cleaning.

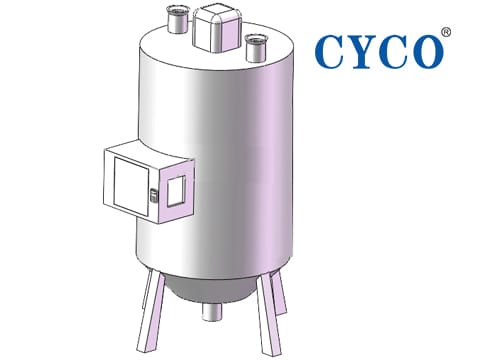

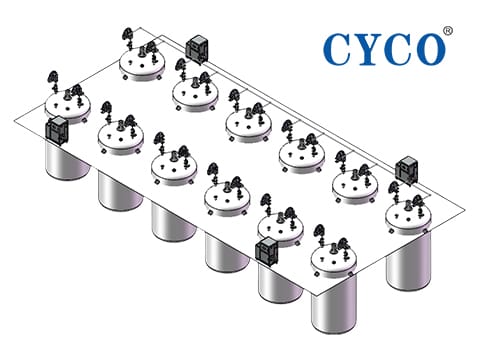

Composition of biological fermentation tank cleaning equipment

The system is mainly composed of a high-pressure cleaning machine, a three-dimensional tank washer, a feeding mechanism, a traction device, a control operating system, etc. These components work together to ensure the efficiency, safety and reliability of the cleaning process.

Advantages of pharmaceutical fermentation tank cleaning machine

The system can remove the internal residues of the fermentation tank in a short time, including dirt, microorganisms and residues. Due to the use of high-pressure water jet technology, the cleaning effect is more thorough, which can reduce production losses and improve product quality.

1. High efficiency: The high-pressure water jet technology is used, the cleaning speed is fast and the effect is good, and a large number of fermentation tanks can be cleaned in a short time.

2. Energy saving: Compared with traditional manual cleaning, it can save a lot of manpower, material resources and water resources, and reduce production costs.

3. Safety: During the operation, the operator does not need to enter the fermentation tank, avoiding the potential safety hazards caused by high-pressure water jets.

4. Environmental protection: The wastewater generated during the cleaning process can be recycled through filtration, sedimentation and other treatment methods to reduce pollution to the environment.

5. Customizable: It can be customized according to fermentation tanks of different manufacturers and models to meet various cleaning needs.

Cleaning Effect