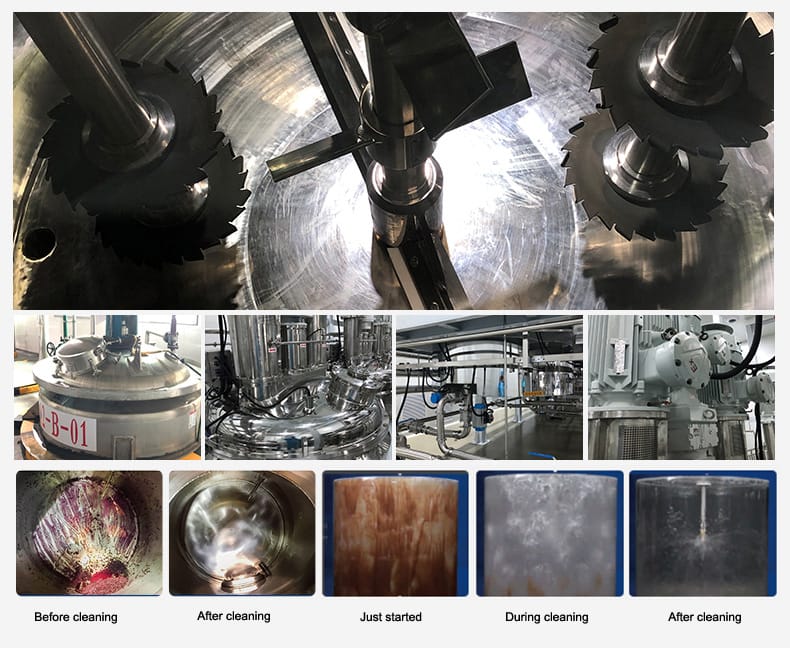

Overview of the ball kettle lifting cleaning system

The ball kettle automatic cleaning system is an advanced industrial cleaning solution. The system combines high-pressure water jet technology, three-dimensional cleaning nozzles and automatic lifting devices to provide efficient and environmentally friendly solutions for cleaning equipment such as reactors.

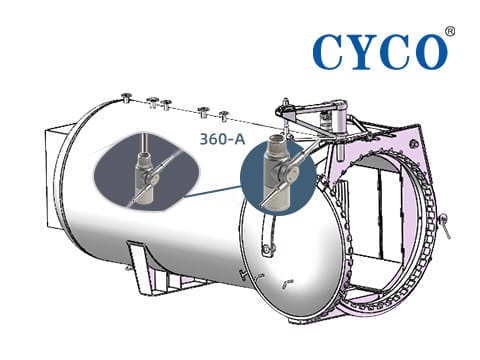

Working principle of the ball kettle lifting cleaning machine

The system uses a high-pressure water generator to generate high-pressure water jets. Through the three-dimensional rotating nozzle, the high-pressure water jet is sprayed to the inner wall of the reactor and the surface of the agitator in a multi-angle and all-round manner. The rotation of the three-dimensional nozzle and the lifting and lowering movement of the telescopic rod enable the water jet to cover any position in the reactor, thereby thoroughly cleaning the dirt and residue attached to the surface.

Technical features of ball kettle lifting cleaning equipment

1. Strong impact force: The high-pressure water jet has a strong impact force, which can easily break the hard scale on the inner wall of the reactor and the surface of the agitator.

2. Full coverage: The design of the three-dimensional rotating nozzle makes the cleaning without dead angles, and can achieve full coverage cleaning inside the reactor.

3. Easy to use: The system is easy to operate and only requires manual assistance to complete the cleaning process without direct manual intervention.

4. High efficiency and energy saving: High-pressure water jet cleaning technology saves water and energy, and is more efficient and environmentally friendly than traditional cleaning methods.

5. High degree of automation: The system can be combined with relevant control systems and safety measures to achieve efficient, environmentally friendly, and high-quality automated cleaning of the reactor.

Composition of the ball kettle lifting cleaning system

1. High-pressure water unit: responsible for generating high-pressure water jets.

2. High-pressure three-dimensional rotating nozzle: realize multi-angle and all-round injection of high-pressure water jets.

3. Positioning and telescopic device: control the lifting and positioning of the nozzle to ensure the comprehensiveness and accuracy of cleaning.

4. Paddle positioning device (if agitator cleaning is involved): used for positioning the agitator to ensure the stability and safety of the agitator during the cleaning process.

5. Sealing device: ensure that the water jet will not leak during the cleaning process and improve the cleaning effect.

6. Electronic control system: control the overall operation of the control system, including the coordination of high-pressure water units, nozzles, telescopic devices, etc.

Performance parameters of ball kettle lifting cleaning device

1. Water jet pressure: adjustable according to specific needs, usually up to tens to thousands of bars.

2. Nozzle rotation speed: can be adjusted according to cleaning needs.

3. Telescopic device lifting range: customized according to the height and diameter of the reactor.

4. Cleaning efficiency: compared with traditional cleaning methods, it can significantly improve cleaning efficiency and quality.

Application field of ball kettle lifting cleaning machine

Widely used for cleaning of various kettles in many industries such as pharmaceuticals, food, beverages, coatings, building materials, chemicals, pigments, resins, scientific research, dairy products, daily chemicals, cosmetics, bioengineering, agricultural engineering, processing tools, petroleum, new energy, etc.

Cleaning Effect