Features of tank high-pressure cleaning system:

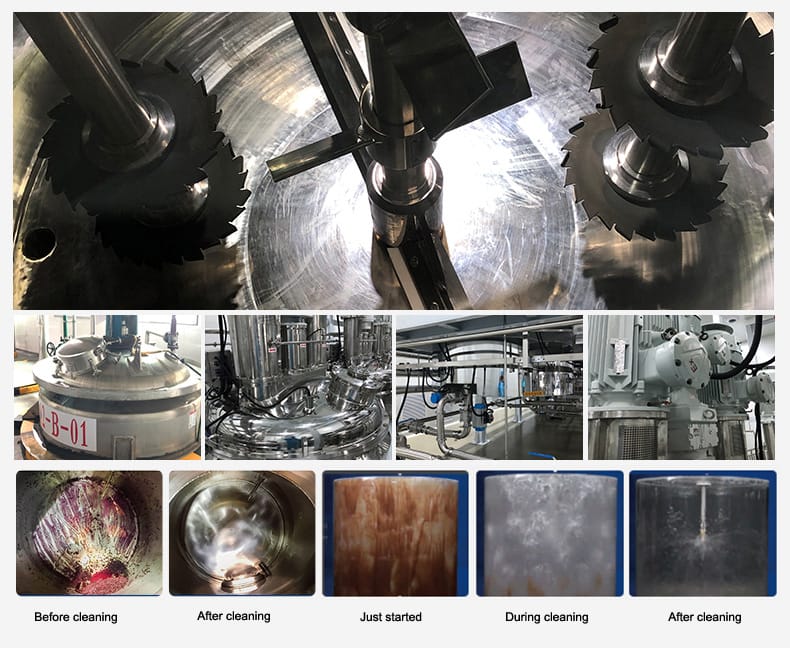

1. Efficient cleaning: High-pressure water is generated by a high-pressure pump or a booster, and reaches the three-dimensional rotating nozzle through a high-pressure pipeline, converting high-pressure and low-flow water into multiple low-pressure and high-flow jets (high-pressure water jets). The powerful impact force of the high-pressure water jet is used to impact the object to be cleaned, remove the dirt, and thus achieve the purpose of cleaning.

2. Three-dimensional rotation: The three-dimensional rotating nozzle can achieve 360° cleaning without dead ends, ensuring that every position on the inner wall of the tank can be effectively cleaned.

3. High degree of automation: The entire cleaning process does not require manual entry into the tank. Through automated equipment and control systems, a series of automated processes such as residual oil discharge, tank steaming, cleaning, sewage recovery, drying, and testing can be completed.

4. Environmental protection and safety: The wastewater generated during the cleaning process can be treated through the treatment system to reduce the impact on the environment. At the same time, since there is no need for manual entry into the tank, the safety of the cleaning process is improved.

Working principle of tank high-pressure cleaning equipment:

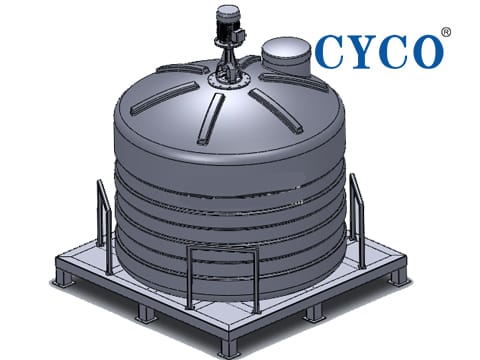

CYCO spray tank automatic high-pressure cleaning system is mainly composed of water supply device, high-pressure pump, automatic pressure regulating device, high-pressure cleaning machine, three-dimensional tank washer and telescopic lifting device.

1. The water supply device is pressurized to a high-pressure state by a high-pressure pump and sprayed out through the rotating nozzle of the three-dimensional tank washer.

2. The three-dimensional tank washer rotates through hydraulic drive to efficiently and automatically perform 360° no-dead-angle cleaning.

3. The three-dimensional tank washer feeding mechanism can realize the precise alignment of the high-pressure cleaning machine and the tank mouth, ensuring that the cleaning head can be accurately placed at the position to be cleaned.

Application field of tank high-pressure cleaning machine:

CYCO tank cleaning system is widely used in the cleaning of liquid tanks, road tank trucks, railway tank trucks and tank containers. It can not only clean all kinds of tank trucks transporting dangerous chemical products, such as tank trucks loaded with BDO, RNMP, animal oil, vegetable oil, alcohols, ethers, organic solvents, acids, alkalis and other chemicals, but also can be applied to tank trucks of different lengths, such as 20-48m tank trucks.

Precautions for tank high-pressure cleaning machine:

When using the tank cleaning system, you need to pay attention to some problems in installation and use. For example, when installing the three-dimensional tank washer feed mechanism, if the column foundation is too high, it may cause the tank cover of the cleaning machine to fail to cover the tank truck mouth. In addition, during the use of the system, it is necessary to pay attention to the breakage of the chain on the C-tube and the overload shutdown of the feed motor. These problems may affect the normal operation of the system.

In general, the Changyuan tank cleaning system is an efficient, safe and environmentally friendly tank cleaning equipment that can meet the cleaning needs of different tanks.

High-pressure tank cleaning system application industries:

Widely used for cleaning tank containers in 200+ industries including pharmaceuticals, food, beverages, coatings, building materials, chemicals, pigments, resins, scientific research, dairy products, daily chemicals, cosmetics, bioengineering, agricultural engineering, processing tools, petroleum, new energy, etc.

Cleaning Effect