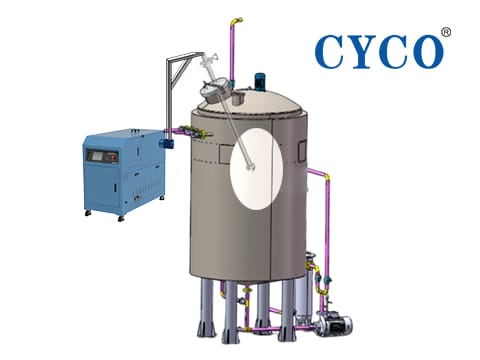

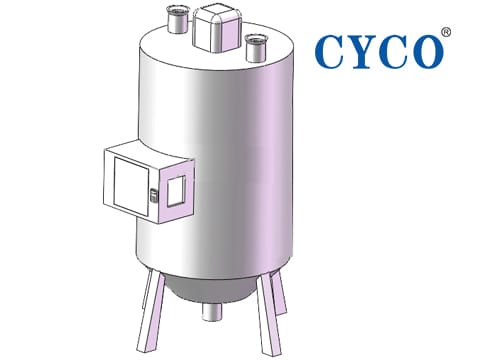

CYCO tank automatic cleaning system has the characteristics of high degree of automation, good cleaning effect, energy saving and environmental protection. It is widely used in tank cleaning operations in petrochemical, food and beverage, pharmaceutical and other industries. Flexible configuration, one tank one policy, customized on demand.

Composition:

High-pressure water pump: It is the power source of the entire system, and the pressure range can be from 10-200bar or even higher.

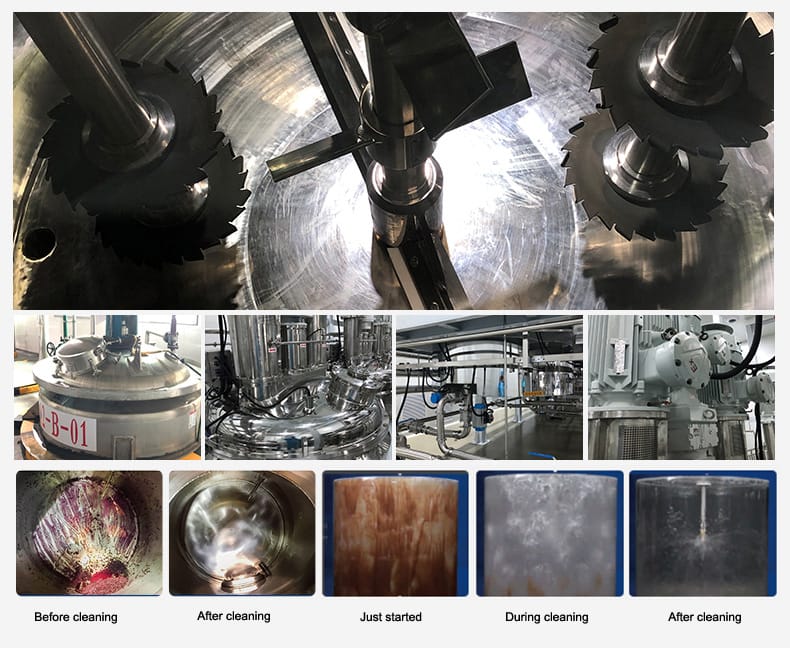

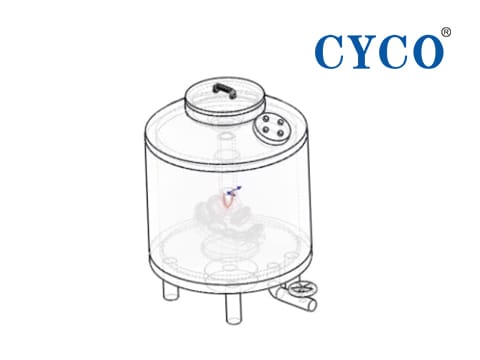

Three-dimensional cleaning nozzle: The nozzle can rotate 360° to ensure that there is no dead angle in the cleaning.

Lifting device: Through the lifting and lowering movement of the lifting device, the nozzle can move up and down in the tank, thereby cleaning different height areas of the tank.

Control system: PLC one-button cleaning control platform, including the start, stop, pressure regulation of the high-pressure pump, and the rotation and lifting of the nozzle.

Delivery pipeline: Used to deliver water or cleaning agent to the cleaning nozzle.

Portable design: The system can be installed on a mobile bracket or frame, which is convenient for moving to different tanks for cleaning, and is suitable for multi-tank cleaning occasions.

Camera or sensor: The system can integrate a cleaning effect monitoring device

Application areas:

Widely used in tank cleaning operations in the pharmaceutical, food, beverage, coating, building materials, chemical, pigment, resin, scientific research, dairy, daily chemicals, cosmetics, bioengineering, agricultural engineering, processing tools, petroleum, new energy and other industries.

Cleaning Effect