The main working principle of the automatic cleaning system for medium and large fermentation tanks is to control the opening of the water pump, the control of each valve and the action control of each mechanism through the PLC electronic control system, and use the cleaning liquid to drive the high-pressure three-dimensional cleaning nozzle to perform three-dimensional, blind-spot-free full coverage of the tank for cyclic cleaning.

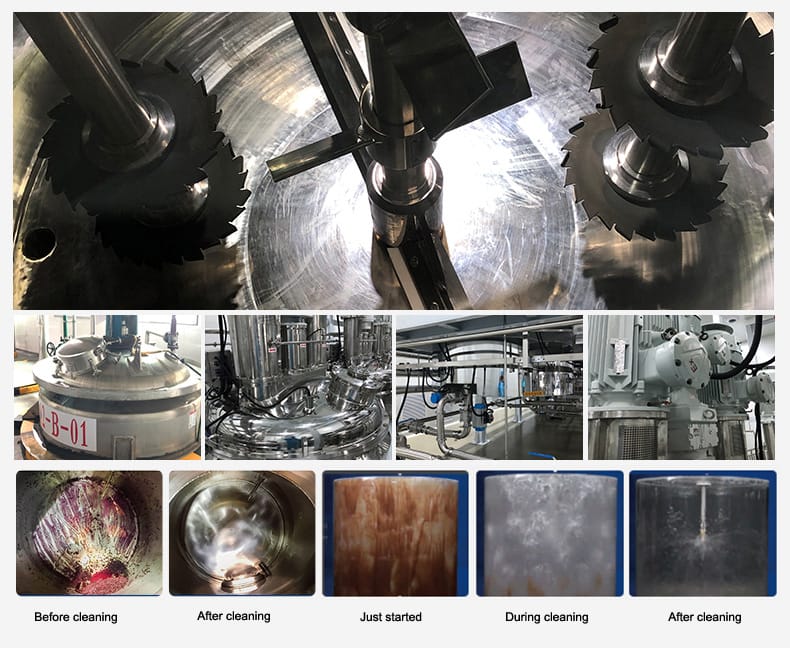

The fermentation tank not only has cooling coils, but also has reinforcing rib beams, stirring blades and other special components. Due to the complex structure, automatic cleaning has always been a difficult task. The traditional cleaning method is to manually go down the tank and use a water gun for cleaning. The working environment is relatively harsh, the safety hazard risk is high, the labor intensity is high, and there are also uncertain factors in manual cleaning. Especially for large fermentation tanks, it is more obvious.

The automatic cleaning equipment for fermentation tanks developed and produced by our cleaning R&D team has been successfully applied to major domestic pharmaceutical companies after many improvements and optimizations.

Principle and introduction of automatic cleaning equipment system for fermentation tanks:

The working modes are semi-automatic and fully automatic. The fully automatic control has a high degree of automation. Only the operator needs to monitor and control the entire cleaning process and assist. It is no longer necessary to manually enter the tank for cleaning, which adds a guarantee for the safety of workers and reduces the workload of workers. It also improves work efficiency and can greatly shorten the cleaning time, thereby saving more cleaning agents and truly saving time, effort and cost.

Pump protection – anti-idling, anti-pressure overload, anti-overheating functions;

Automatic start and stop – the main pump automatically starts and stops when the cleaning water is used. When the cleaning process needs to be paused, close the cleaning water valve, the main pump stops working and enters the standby state. After the water valve is opened again, the main pump restarts;

Automatic adaptation – an integrated cleaning mobile trolley with swing angle, tilt arm, pipe delivery and pipe collection;

Sanitary hose – a 50Bar pressure-resistant sanitation composite hose with a sanitation quick-install interface design;

Technical description of the fermentation tank cleaning system:

The cleaning targets are various fermentation tanks, mixing tanks, and reactors;

The cleaning vehicle is in place – after the rough step is in place, open the manhole cover, manually rotate the cleaning cantilever 90 degrees to the center of the manhole, then lock it, and step on the foot brake on the 4 universal wheels to prevent movement. Connect water, electricity and gas, adjust and install the tank washer and manhole sealing fixing plate through the screw lift, and confirm the installation alignment seal;

Start cleaning – After the operator starts the system, it enters the automatic cleaning state, divided into 3-5 height positions, and symmetrically cleans at 2 points along the center line of the tank (or uses triangular points), without manual intervention; the steps of automatic cleaning are shown in the scheme diagram; the entire cleaning process only requires 1 person to control and complete; the cleaning time of each position can be set and changed manually, but the password needs to be entered in the specified page on the touch screen.

End of cleaning – After the cleaning is completed, the system automatically retracts the telescopic arm, vertically downward, rotates back 33 degrees, and rises back to the original position. At the same time, the coiler is controlled by the servo motor and the induction switch to rotate and pause, so as to achieve synchronization of its actions, retract the water pipe in time, disconnect the water, electricity and gas, and manually turn the entire arm 90 degrees back to the original position and lock it. Estimated cleaning time – about 30-45 minutes/tank, depending on the customer’s cleanliness requirements, the diameter of the tank and the number of cleaning points set;

Features of fermenter cleaning equipment: The equipment developed by CYCO spray fermenter automatic cleaning is mature and stable, which can replace manual cleaning. It has a high degree of automation and only requires one person to operate, which greatly improves the cleaning efficiency, reduces labor intensity, and has good cleaning effect. It does not need to enter the tank. The left and right sides of the stirring shaft are cleaned separately by the mechanical arm. The depth of descent, cleaning time, and the number of cleaning points can be adjusted according to the actual situation. Because it adopts a mobile cleaning method, it uses the existing manhole without the need for additional openings, which is particularly suitable for 50-500m³ fermenter cleaning.

Application range of automatic fermenter cleaning equipment: The automatic tank cleaning system is mainly used for full cleaning in cubic tanks, including automatic cleaning of various three-dimensional tanks such as medium-sized and large fermenters.

Cleaning Effect