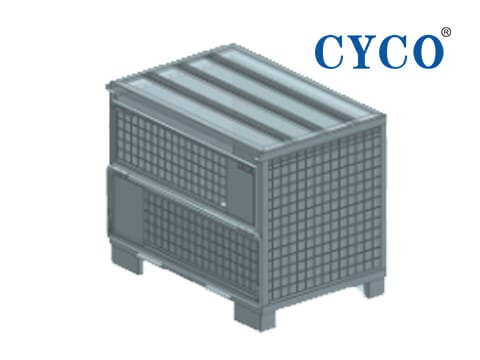

CYCO spray sales production turnover tank automatic cleaning system is an efficient and automated cleaning equipment, designed for cleaning all kinds of turnover barrels. The system combines mechanical, electronic and cleaning technologies, can achieve all-round, no dead angle cleaning, greatly improving the cleaning efficiency and quality.

System composition

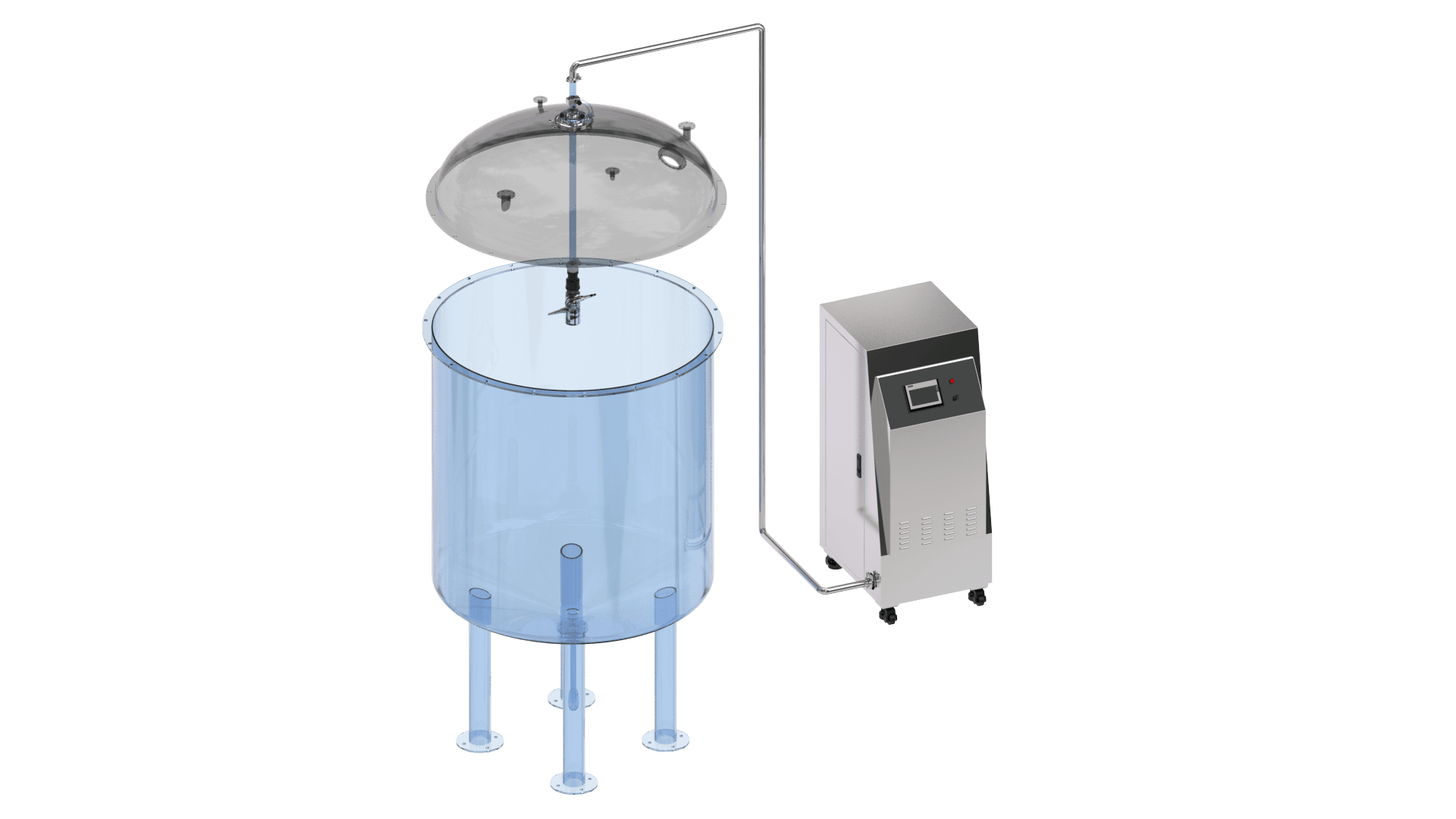

The turnover tank automatic lifting and rotating cleaning system is mainly composed of the following parts:

1. Cleaning room: a closed space for accommodating turnover tanks and performing cleaning operations.

2. Lifting mechanism: responsible for lifting the cleaner to the inside of the turnover tank to adapt to turnover tanks of different heights.

3. Rotating mechanism: drives the cleaner to rotate 360° inside the turnover tank to ensure all-round cleaning.

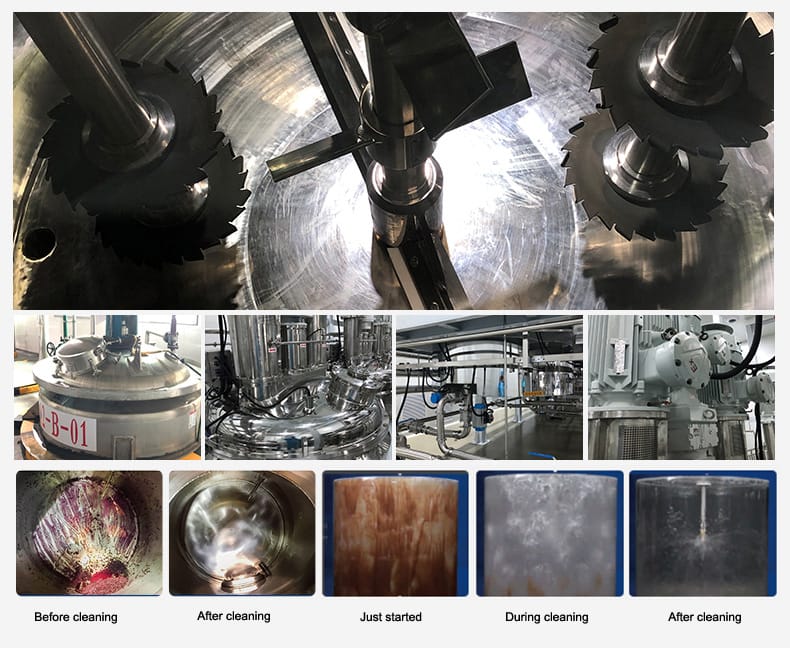

3. Cleaner: adopts three-dimensional high-pressure rotary cleaning technology to remove stains on the inner wall of the turnover tank through high-pressure water flow and rotating action.

4. Control system: responsible for the operation and control of the entire system, including the start, stop and adjustment of equipment such as water pumps, valves, and motors.

System composition

The turnover tank is manually pushed into the cleaning room, and the cleaning parameters are set through the control system.

The lifting mechanism lowers the washer into the turnover tank, and uses the pressure detection function to prevent abnormal downward pressure from damaging the nozzle mechanism.

The control system starts the water pump and rotating mechanism, and the high-pressure water flow is sprayed through the washer, and 360° rotation cleaning is performed inside the turnover tank.

The cleaning time can be set according to demand, usually 2-4 minutes. After the cleaning is completed, the cleaning head stops rotating and rises to the initial position.

The control system turns off the water pump and rotating mechanism, and transports the turnover cylinder to the next station or manually removes it.

Product advantages

1. High degree of automation: The entire cleaning process does not require manual intervention, and fully automated operation is achieved.

2. Good cleaning effect: The three-dimensional high-pressure rotating water jet cleaning technology can remove stubborn stains on the inner wall of the turnover cylinder and ensure the cleaning quality.

3. Wide range of applications: Suitable for cleaning operations of turnover tanks of different materials and sizes.

4. Energy saving and environmental protection: The system adopts circulating water utilization technology to reduce water resource waste; at the same time, it adopts high-efficiency energy-saving equipment to reduce energy consumption.

5. High safety: The system has multiple safety protection measures, such as pressure detection, water-free power off, etc., to ensure the safe operation of the equipment.

Cleaning Effect