Fully Automatic CIP Cleaning System Solution

CIP devices have been commonly used in the filling equipment of dry, beer, beverage and milk product manufacturers, and have become an indispensable part of the production process. The system is used to clean the inside of production equipment, such as the inside of pipelines and cylinder bodies, which can effectively improve the utilization of equipment and reduce the labor intensity of workers. Even so, a large number of business managers have problems in understanding and managing, as evidenced by the following:

1. Unable to determine the cleaning process correctly, resulting in a large amount of wasted softened water and cleaning solution.

2. Unreasonable selection of cleaning or reflux pumps, either the cleaning fluid cannot reach the equipment to be cleaned, or the closed containers or pipelines to be cleaned cannot be effectively cleaned.

3. The provided self-cleaning system does not allow for a full and clean CIP for its own container.

CYCO CIP Cleaning Solution

The CIP washing station designed and manufactured by CYCO can be widely used in spray drying plant, milk factory, beverage factory, food factory, pharmaceutical and chemical industry. It overcomes the disadvantage of dismantlement for cleaning, reduces the loss of raw materials, and is a reliable guarantee for improving the quality of products.

The CIP cleaning system of CYCO mainly consists of an acid tank, a lye tank, a hot water tank, a fresh water tank, a concentrated acid tank (only contained in the fully automatic CIP), a concentrated lye tank (only contained in the fully automatic CIP), a plate heater, a cleaning solution delivery distributor and a centrifugal pump, etc.

The performance of the fully automatic CIP cleaning system:

Flexible and versatile: the system can carry out pickling, alkaline washing, hot water flushing and other processes individually, or it can be fully automated for cleaning by specific cleaning programs according to the needs. This not only cleans the equipment effectively, but also controls the growth of microorganisms. At the same time, it can be equiped with semi-automatic or full-automatic control system according to the requirements of customers.

Safe and reliable: concentrated acid and lye are carried out in buried concentrated acid and lye tanks. The liquid level in the tank can be automatically controlled and has an overflow protection system. The unique outlet structure prevents the cleaning solution from crystallizing to block the pipeline.

Economic: compared with manual cleaning, it greatly reduces cleaning time and improves work efficiency. The use of cleaning agents and water will be more scientific and reasonable, while the steam consumption is relatively small, which can achieve the purpose of rational use of energy, and as a result, the cost of cleaning is effectively reduced.

Mature PLC control system: years of experience makes our program more perfect, and with the imported high-quality control components, the system can be guaranteed to work for a long time with stability. A user-friendly human-machine interface not only shortens the training time of the operator, but also shows the working status of the key components directly. An easy-to-understand help interface can assist operators in determining and dealing with a wide range of common fault signals, so the equipment can be back to its normal state in time.

Characteristics of the fully automatic CIP cleaning system

1. Low operating costs: can be cleaned without dismantling equipment and pipelines. Compact structure with a small footprint, easy to install and maintain. It can effectively clean tank containers, pipelines and other equipment, the whole cleaning process is run in the closed tank containers and pipelines, which greatly reduces the chance of secondary pollution.

2. Reduce cleaning time greatly: can be divided into one way to four ways according to production needs. Two or more ways can clean the same or more than two areas at the same time, and can also clean while producing in the process, which greatly reduces the time of CIP cleaning in the production.

3. Extracorporeal circulation system: can reduce energy consumption effectively.

4. Recycle water system: reduce the use of water efficiently.

5. Cleaning program can be automatic: especially the fully automatic CIP cleaning system can detect, add, release, display and adjust the cleaning solution automatically. Because of its reliable operation, high degree of automation, simple operation, and good CIP cleaning effect, it is more suitable for the sanitary requirements and production environment requirements of modern large-scale fluid medicine and food processing technology.

Technical characteristics of fully automatic CIP cleaning system equipment

Compact, small footprint, modular unit, all of which are easy to operate or maintain, and to interface with existing equipment.

Support multi-module expansion (hardware, and softwar) and automation control, easy to connect with the whole system of the plant.

Equip with an online cleaning and sanitizing port.

Separate dispensing place without contaminating the production area.

Cleaning tanks, pipelines and other equipment in place conveniently and effectively, and the entire cleaning process is carried out in sealed tanks and pipelines, with no risk of cross contamination.

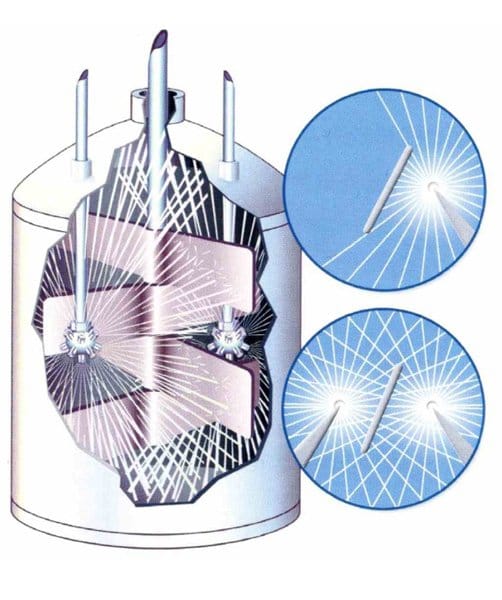

The system is mainly composed of alkali tank, acid tank, hot water tank, various pipelines and pneumatic valves, pressure transmitter, conductivity meter, platinum RTD and control system. It utilizes a centrifugal pump to convey cleaning fluid for forced circulation in the pipeline and equipment to achieve the purpose of cleaning.

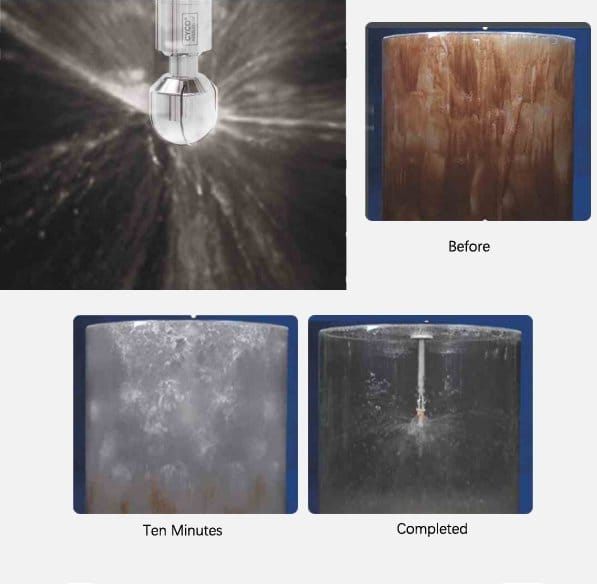

In actual operation, the practical use of a fully automated CIP cleaning system must be combined with the equipment and pipeline arrangement of the workshop as well as with the cleaning head. While using, adjust the parameters of the equipment according to the actual situation to ensure the best cleaning effect.

CIP cleaning systems are widely used in the cleaning of pipelines, tanks, containers and equipment with high sanitary requirements and production environments, such as large-scale fluid pharmaceutical factories, milk factories, beer factories, condiment factories and general food factories.