CYT Ton Barrel Cleaning Machine

- Maximum flow: 20L/min

- Maximum pressure: 120Bar

- Machine power: 16KW

- Cleaning inner diameter: ø1-5 meters

- Host size: 1800*2950*10000mm

- Net weight: 2800KG

Performance characteristics:

- Great mechanical effect. The combination of pressure and flow produces a powerful impact jet, which has an impact several times more than other products, and can achieve a larger cleaning distance and range. The kinetic energy of the flushing water flow generated by the high-pressure pump can effectively remove the residue on the container wall. Positive impact from the vertical direction helps penetrate dirt. The tangential force helps remove residue from the container walls.

- Low leakage. 3% of the leakage volume, 97% of the cleaning fluid is used for cleaning, which allows the three-dimensional rotating nozzle to maximize the mechanical power and greatly reduce the dependence on time, chemical reactions and temperature. IBC three-dimensional rotating cleaning nozzle saves water, time and energy, only 20%-50% of other products.

- Realize three-dimensional cleaning. It has accurate and completely repeatable, reliable and tight spray trajectory, directional impact, 360° full spherical coverage, 2-5 minutes of cleaning time, which reduces the downtime of the barrel; reduces resource consumption, correspondingly reduces sewage treatment costs; cleaning and cutting, Reduced chemical use reduces environmental pollution.

- Standardized model configuration. All parts are precision machined, and parts of the same model are highly interchangeable, making maintenance simple and convenient to ensure efficient cleaning.

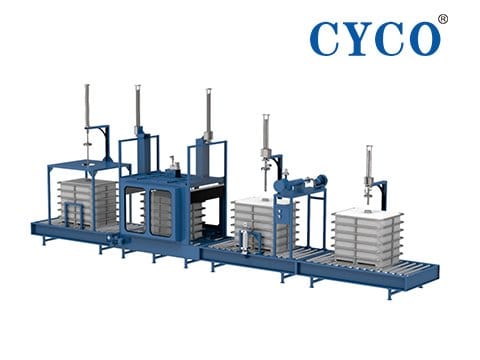

Advantages of automated cleaning lines:

- Independently designed according to customer working conditions, fully automated internal and external cleaning, disinfection and drying, simple operation, stable performance and high cleaning efficiency;

- The cleaning time of each barrel is about 2-5 minutes/barrel, saving manpower and material resources, greatly improving production efficiency, and greatly reducing labor intensity;

- Solve the problem of difficulty in recruiting cleaning workers, greatly improve the working environment and make it more environmentally friendly;

- The system can be equipped with large, medium and small pressure cleaning to solve cleaning problems under various working conditions;

- The system adopts a precision 360° full coverage high-pressure three-dimensional cleaning head, which has high impact and low liquid consumption;

- Only 1-2 manual operations are required, the economic benefits are high, the investment cost can be recovered quickly, and the quality and production capacity are also greatly improved.

Automated cleaning line selection and configuration:

- Internal and external cleaning system

- Drying system

- Circulating water cleaning system

- Explosion-proof configuration

- Disinfection system

- Water heating system

- Leak detection system

- Solvent alkali cleaning

- PLC touch control

Cleaning line operation process:

- The operator uses an electric forklift to deliver the PE ton barrel to the cleaning roller, push the ton barrel to a fixed position, and open the bottom sewage outlet;

- Confirm that the storage tank has enough cleaning fluid, start the system, the drum line brings the ton barrel into the cleaning room, position multiple nozzles on the side and above to start spraying water for cleaning, and the rotating mechanism starts to rotate. The cleaning is completed in about 2 minutes, and the ton barrel is It is brought into the next drum line by the drum line and starts cleaning the inside. After the positioning is OK, the lifting mechanism lowers the sealing cover and the can washer and installs it into the tonnage mouth; the nozzle starts 360-degree cleaning;

- After the set cleaning time, the cleaning automatically ends. The automatic door opens, and the ton barrel leaves the cleaning room to the next drum line. The positioning tilting mechanism is ejected to tilt the ton barrel and pour out the remaining water;

- After the completion, the ton barrels enter the next conveyor line, the bottom sewage outlet is closed, and the forklift takes away the ton barrels, and the cycle continues;

Application scenario diagram:

Dongguan Changyuan Spray Technology Co., Ltd. (CYCO) was established in 1997 and is currently the leading manufacturer of industrial nozzles. High quality casting is highly trusted, CYCO has established good cooperative relations with more than 200 global customers, and passed the IATF16949 certification of Global Sai in 2018.

CYCO has specially designed three nozzles for desulfurization of marine exhaust gas, namely: spiral nozzle, short body full cone nozzle, and large flow full cone nozzle. The raw materials are plastic, stainless steel and silicon carbide. Professional achievements in the future, let the professional quality of CYCO to protect the blue sky, let’s work together.