Features:

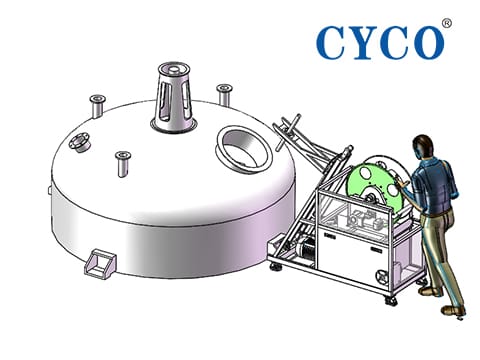

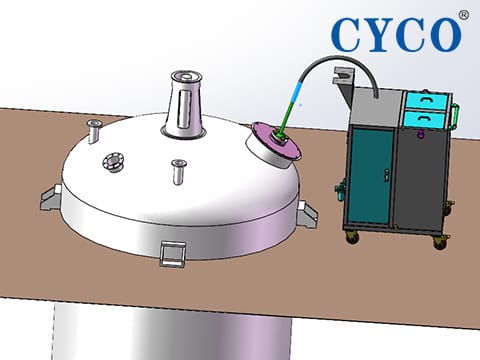

The mobile intelligent cleaning trolley for reactors consists of a retractable mechanical arm, an electric reel, a movable cleaning trolley and a reactor cleaning nozzle. It is suitable for cleaning conditions in non-electric or flammable and explosive environments, cleaning conditions that require mobility and sterile environments, and field operations such as oil production plants and chemical sites far away from power sources.

Composition:

1. Intelligent control unit: equipped with a touch screen or remote control terminal, users can easily set and monitor cleaning tasks.

2. High-pressure cleaning system: The high-pressure pump provides 5-300 bar (adjustable) cleaning pressure to meet the needs of different reactor bodies. The rotating nozzle efficiently sprays water or cleaning media to cover every corner of the reactor body.

3. The industrial casters of the mobile trolley are equipped with brakes to support easy movement and fixation. Some models are equipped with electric power assist function to improve mobility.

4. Cleaning head device: telescopic or lifting design, which can automatically adjust the cleaning range according to the depth of the reactor body. The material is usually food-grade stainless steel (304 or 316L).

5. Pipeline and connection system: equipped with high-pressure hose or hard pipe to adapt to different working pressures and cleaning media.

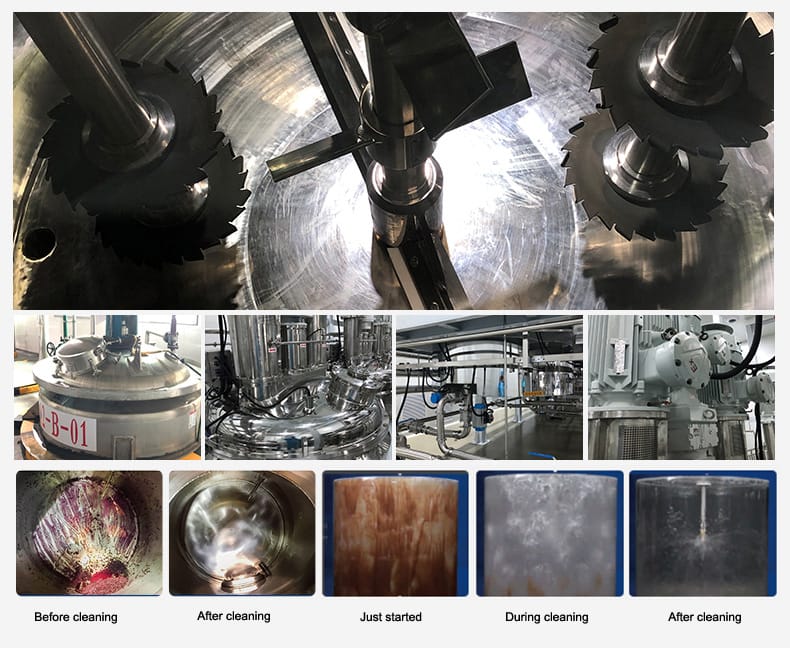

Case pictures:

This equipment is widely used for cleaning tanks/kettles/ton barrels/closed containers in industries such as pharmaceuticals, food, beverages, coatings, building materials, chemicals, pigments, resins, scientific research, dairy products, daily chemicals, cosmetics, bioengineering, agricultural engineering, and processing tools. It is an important tool to ensure production safety and product quality.

Cleaning Effect