CYCO-15 Three-Dimensional Bottle And Can Cleaner

CYCO-15 three-dimensional cleaning of small and medium-sized storage tanks, high-pressure cleaning, and independent gearbox design achieve 360-degree full coverage cleaning with a cleaning rate of 98%. The cyco-05 bottle cleaning nozzle reduces the need for dangerous and time-consuming manual tank cleaning. It is ideal for high-impact cleaning of various kettles, tanks, water tanks, pools, tanks, barrels, cabins and other industrial containers as well as other types of containers in more than 200 industries such as biological fermentation, biopharmaceuticals, food and beverages, new energy electrolytes and petrochemicals. choose.

Parameter:

- Maximum cleaning diameter: 50 feet (15.3 meters)

- Type: gear reduction drive

- Weight: 4.1 kg

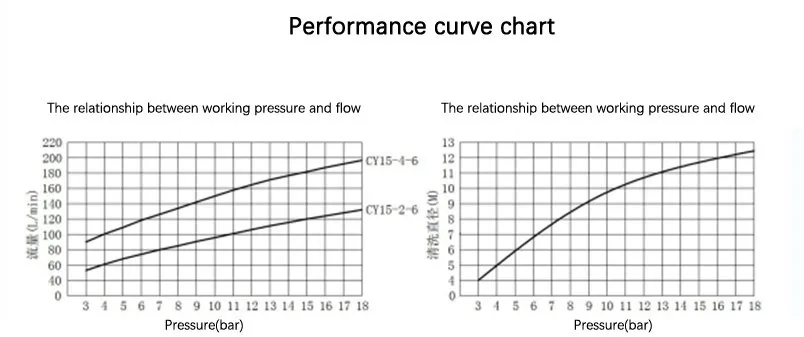

- Working pressure: 3.4-25 bar

- Flow rate: 6-12 m/h

- Cleaning cycle: 5-35 minutes

- Cleaning angle: 360°

- Material: 316L, PTFE

- Minimum installation diameter: 110mm

- Connection: 1-1/2 NPT or BSPT(F)

- Operating temperature: ≤200°F (93°C)

- Cleaning medium: water, weak acid solution, weak alkali solution

Features:

- 360° cleaning without dead corners: When the cleaner is working, first confirm that the four nozzle grooves are in the vertical direction as shown in the figure, and select the appropriate nozzle angle according to the size of the cleaning tank to ensure the cleaning impact force. (The larger the cleaning bottle and tank, the fan-shaped nozzle The angle should be as small as possible to just cover the bottles and cans, so as to achieve all-round 360° cleaning.

- Sealing: Dynamic sealing is used at the leakage point to reduce leakage and save cleaning fluid. At the same time, a greater impact force of water flow is produced.

- Higher impact: The nozzle adopts a unique steady flow design, which can make the jet water more concentrated, have greater impact and clean more thoroughly.

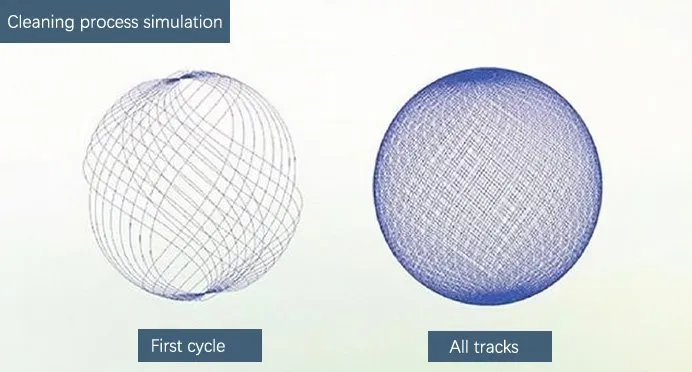

Cleaning process simulation:

Applications:

Three-dimensional cleaning of small and medium-sized containers, suitable for high impact cleaning of reactors, tanks and industrial containers in 200+ industries such as biological fermentation, biopharmaceuticals, food and beverages, new energy electrolytes and petrochemicals, such as fermentation tanks, beer tanks and pharmaceutical tanks. , chemical tanks, chemical processing tanks and other occasions that require high impact cleaning