CY-SS CIP Cleaning Nozzle

The nozzle head is flush with the equipment mouth when not inuse (The equipments are spraydrying chamber, cyclone, fluidizedbed, storage tank, pipeline, etc.). During nozzle operation, wateris pumped to the nozzle under pressure, which put the nozzle headinto the correct position in the tank to clean the equipment. Oncethe water stops, the nozzle head automatically retracts to itsoriginal position and stops liquid residue in time.

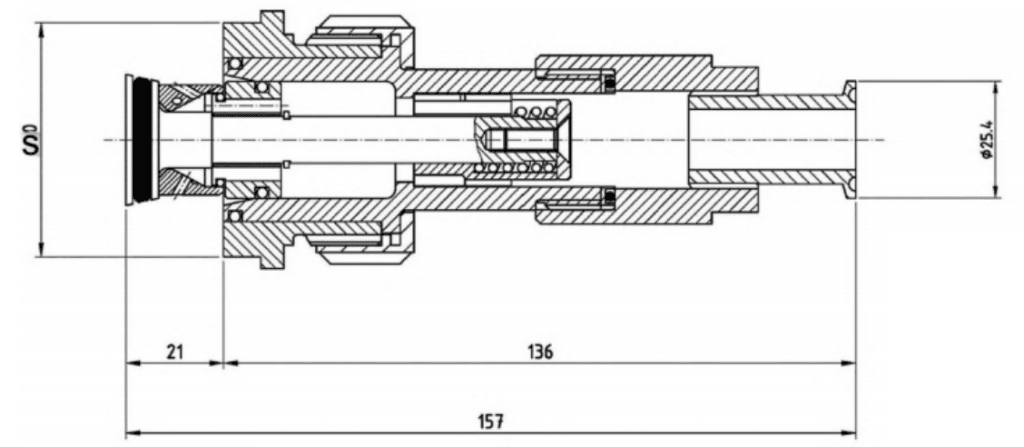

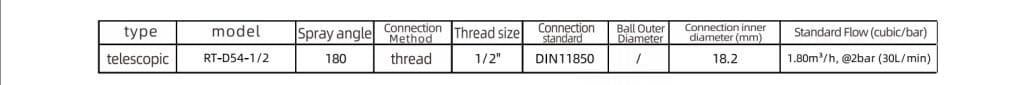

Specification:

Wetting Radius

Up to 4.5m

Impact Cleaning Radius

Up to 1.8m

Spray Angle

70-150°

Maximum Operating Temperature

120°C

Maximum Ambient Temperature

150℃

Supply Pressure

1.8-4 bar

Recommended Pressure

2bar

Liquid Flow

1.8 m³/h @ 2 bar

Features:

- High-Impact Cleaning, Hygienic design

- Minimum cleaning fluid consumption

- Direct fluid drive

- Automatic lubrication

- 1.8m impact radius

Performance:

Application:

Food and beverage industry, pharmaceutical industry, biological fermentation, petrochemical industry, spray drying chamber, cyclone separator, fluidized bed, reactor, storage tank, pipeline, etc.